Larry, Zac and Grant Build a Boat

Page 6

Gunwale scaphing

Here are the first two scarph joints made with the scarphing sled. One of them is hard to see in the photo -- or in person.

Saturday, March 1

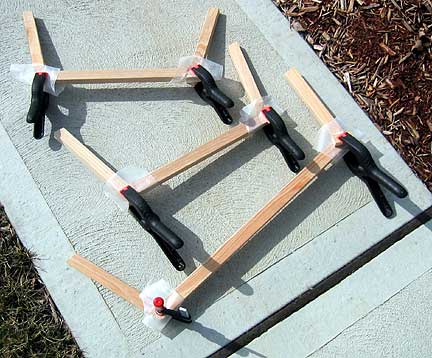

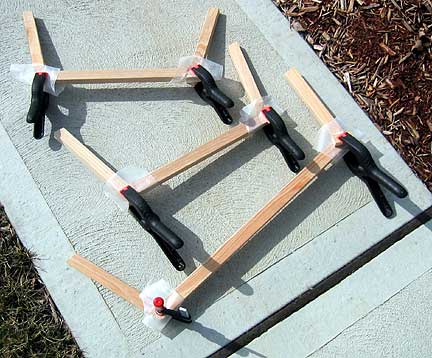

Larry, Zac and Grant scarphed the boat's bottom and the its sides, and glued up the ribs (with Gorilla Glue) after Zac had eased all their inside corners on the vertical belt sander. Here are the ribs, out on the sidewalk, waiting for the glue to cure:

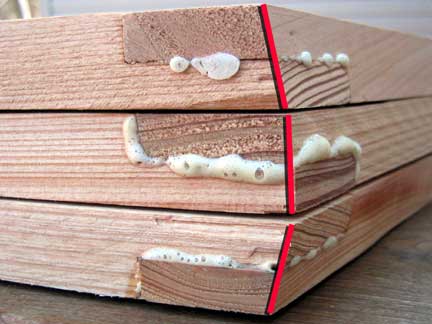

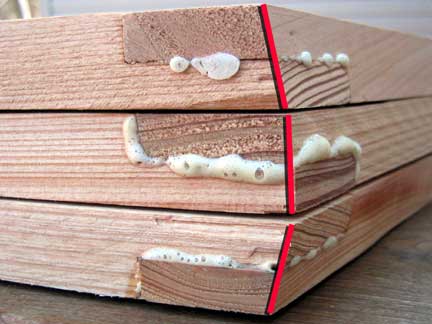

The photo below shows how Gorilla Glue expands -- and how the ribs are shaped (see red lines added to photo) to fit the sides of the assembled boat:

Grant will clean up the glue joints and plough limber holes in their bottoms. They'll be ready to use next Saturday when we assemble the boat:

Grant will clean up the glue joints and plough limber holes in their bottoms. They'll be ready to use next Saturday when we assemble the boat:

Scarphing the bottom

didn't go quite as smoothly as anticipated. First we tried using Terry's belt sander. It seemed too aggressive and not easily controlled. So we switched to sanding blocks Grant had made by glueing course sandpaper to some 3/4" plywood. (See later photo.) This is the scarph joint in the bottom plywood -- in progress.

Scarphing the sides

OK, we have the two plywood panels that make the bottom all glued up and clamped with a board nailed across the joint. Now we'll work on the side panels.

Above: The sanding block in use.

Above: The sanding block in use.

Above: Larry using the sanding block on the sides. We found it was important to use the shop vac frequently to keep sawdust out of plywood layers. (We did not tack the layers per the instruction sheet. We'll do that next time.)

Above: Larry using the sanding block on the sides. We found it was important to use the shop vac frequently to keep sawdust out of plywood layers. (We did not tack the layers per the instruction sheet. We'll do that next time.)

Go To Page 7 . . .

Click on an ad -- doing so helps pay for this website.

(Ads are not selected by the webmaster.

Google selects advertisers based on page's content.)

|