|

The Story of Hathor (Continued) CHAPTER 2, THE RESTORATION PROCESS

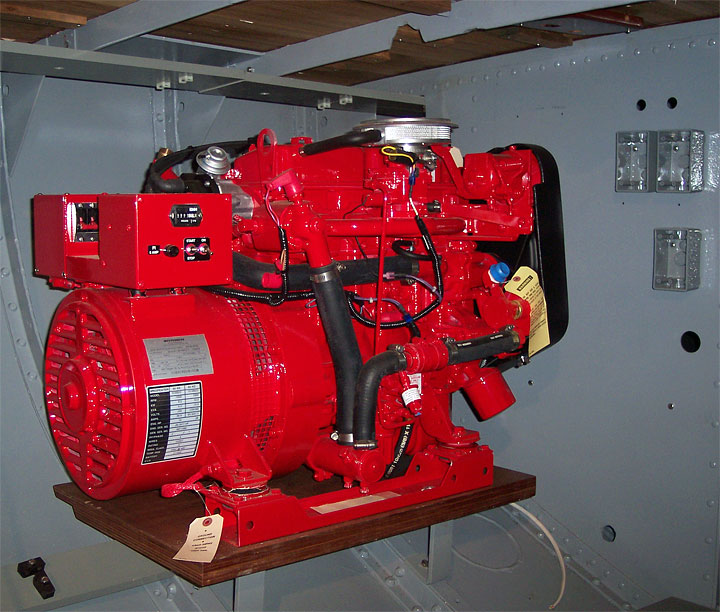

Rebuilt engine box ready to be placed. The canopy was in rough condition but still salvageable. We spend a year stripping, sanding and refinishing. Fidel Sierra stripped off three layers of old roofing material on the top, then scraped the adhesive and tar residue off, and then sanded the entire top. We were able to find a molding cutter that would recreate the same cross section that was on the strips of wood originally used for the canopy and we made about 200 feet of new roof strips in fir to match the originals. Earl Lima went through and replaced any questionable wood or any wood that had been damaged. The posts that hold up the canopy were all taken off, stripped, sanded, stained, and varnished. The bottom of most of them had some rot where they had rested on the old deck, so we cut off any questionable material and put a new bottom section on all of them. Fidel Sierra also stripped all the old paint and varnish on the underside of the canopy and applied new stain and varnish. New electrical wires for the running lights and deck lights recreating the original 1898 layout were worked into the canopy.

Forward deck in March, 2009 showing new hand rails, cap rail, and powder coated stantions. Engine box has not yet been re-installed.

Front of cabin, March, 2009, showing new window with lower original sill duplicating the original, new door jams and new molding around lower panel.

Side of cabin, March, 2009, showing new window frames, new sill, and new moldings around lower panels.

Aft deck, March, 2009. The boxes stacked up in the center are for life preservers. The old smoke stack was badly rusted in places so a new smoke stack was made out of aluminum by Stuart Tank Company.

Original stack used as pattern. Click on photo for larger image. We tried to use the old hand rails but they had been badly abused and, in the front, badly weathered and cracked. We decided to replace them mostly on the basis of appearance, the new wood would have a different color and grain than the old wood. Archie McDonald cut new ones from solid mahogany planks that were two inches thick and 12 inches wide and shaped the curving cross section to duplicate the original. The stanchions that hold up the hand rails were stripped of old paint, sand blasted, then powder coated and baked. We pulled the propeller shaft and cleaned the bearings. Although they had been underwater from time to time, the grease had protected them and they appeared in good shape. One of the propeller shaft couplings had a couple of bolts that had loosened and had been scored and bent so Bob Radewan made new ones. We replaced the stuffing box with a modern leak free seal.

Click on propeller for larger image. The rudder through-hull bushing and stuffing box had been bent and stretched so the threads no longer had a consistent pitch and the packing nut would not screw on. Bob Radewan of Ernie Styberg's company made a new bushing out of a 5-inch diameter billet of solid bronze. Talk about jeweler's work, this bushing was absolutely gorgeous. I wish I could have mounted it as sculpture. We added a thrust bearing to better carry the several hundred pound weight of the rudder. We added two masts to give the boat a little more height. Although these are not original, we took some artistic license to add them because similar masts were on most other boats of the period.

New 10 kw, 120-volt Westerbeke generator installed. Still to come is new electrical wiring for a 12 volt general boat lighting and a 110 volt system for food service (coffee pot, hot plates) and decorative lighting. Also plumbing for water supply and waste, holding tanks, deck drains, a new steering system with hydraulic steering replacing the original cable system, and new engine controls.

|