3/24/11 -- Learnd today of the passing of Harold H. "Dynamite" Payson, Phil Bolger's stalwart collaborator in years of reviving the home boatbuilding movement. Dennis Hansen's posting is summarised: "Dynamite died last night. Details are sketchy but it sounds as if he suffered a burst aorta. He was rushed from Rockport to Portland but they couldn't save him. The World is a lesser place today with the loss of the wonderful man.

Here's how Dynamite might have made the joint I'm working on today: BUTT JOINT. (You'll have to use your "back" button to return here.)

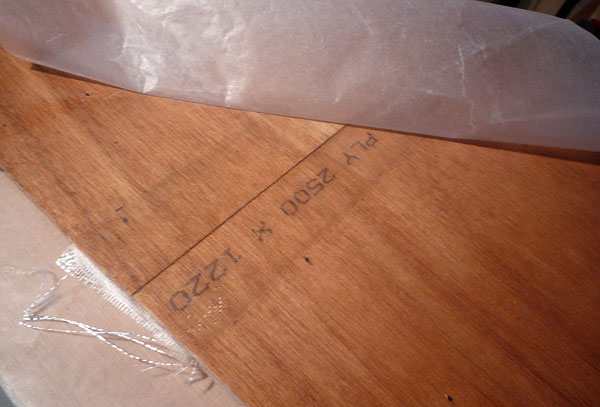

Yesterday I cut one sheet of "1/4 inch*" marine plywood into three strips to begin making the sides of the boat. *Not only is it not 1/4", it is not "4x8" as I expected. (That messed me up as I was laying out the panels. And, I suspect, the boat (a future boat) might be built out of fewer plywood panels. )

I have made quite a few changes to the structure of the boat. There is no doubt of it being a Bevin's Skiff; its shape will be identical to the drawing.

But instead of 3/8" ply, 1-1/2" transom, and chine strips, and one-piece gunwales, and one-piece stem, I'm using 1/4" ply, lots of epoxy resin, a stem and gunwales. of my own design, etc.

I have one side panel made, and will probably have the other side made by Monday. I might need some help with the first major assembly of the two side, stem, transom and frame. There is one step that will be awkward for one person.

The first three photos below show the 6" wide scab weighted with xar wheels and a box of chain.

The last picture shows the outside of the side panel where the butt joint will be taped with 3" wide glass tape. The sanding block is one of many i made using white glue, sand paper, and plywood.

The white plastic piece in one of many cut from 3-ring notbook binders. The tape will be aligned with the pencil marks on both sides of the butt joint, then wetted out with epoxy.

3/24/11 -- Yesterday I bought a Bosch (7 amp, corded) jig saw.

Used it for the first time today, and like many of the reviewers, I found it to be an amazing improvement over my old Craftsman. The Craftsman, even when new, would wander, making it almost impossible to follow a line. For a few years now, the old saw's blade clamp was missing threads on one of its two set screws. And, about a year ago, its blade swivel broke. Look at the blade guide on the new one. It's almost as smooth cutting as a band saw. And the blade clamp works without tools. It even has a blower to keep the cut free of dust. There is an adjustment on how aggressive the stroke angle is for different materials. I love it!

3/24/11 -- Here is the 'glassed butt joint, viewed from the outside. The wax paper is being peeled off the taped joint.

And here is the second side panel, viewed from the inside, with the 6 inch wide scab in place, and its freshly coated joint weighted. After the epoxy sets, the panel's out side will have its joint taped with fiberglas.

|